Introduction

Enterprise Resource Planning (ERP) systems have long been the backbone of business operations, centralizing processes from finance to inventory management. Yet, as businesses face a rapidly evolving landscape of market disruptions, regulatory demands, and technological advancements, traditional ERP solutions are struggling to keep pace. Today, enterprises are no longer satisfied with merely tracking past performance—they require real-time insights, predictive capabilities, and simulations to guide decision-making. This is where the concept of digital twins in ERP systems comes into play.

A digital twin is a virtual replica of physical assets, processes, or systems that continuously update with real-time data. When integrated into ERP, digital twins provide businesses with the ability to simulate various scenarios, forecast potential challenges, and optimize operations before real-world changes are implemented. In this blog, we’ll delve into what digital twins in ERP are, why they’re important, and how industries are adopting them to foster smarter decision-making.

Why Traditional ERP Isn’t Enough

While traditional ERP systems have certainly evolved over the years, they still have several limitations that make them ill-equipped to address today’s dynamic business needs. Let’s explore the challenges that ERP systems face in the current business environment:

- Static View: Traditional ERP solutions offer basic reporting, dashboards, and data visualization tools, but they cannot provide real-time simulations of future scenarios. This means that decision-makers are left to rely on historical data rather than being able to predict what will happen next.

- Limited Predictive Power: While ERP systems are excellent at tracking past performance, they struggle to proactively forecast potential outcomes, such as market shifts or production delays. In industries where timing and accuracy are critical, relying solely on historical data can lead to missed opportunities.

- Complexity in Operations: As industries such as manufacturing, logistics, and healthcare become increasingly complex, businesses need real-time adaptability. Static ERP systems, which are designed to process large amounts of transactional data, cannot provide the level of flexibility needed to respond quickly to operational disruptions or changing market conditions.

- Growing Risk Environment: In today’s fast-paced market, businesses face numerous risks such as supply chain disruptions, changing regulations, and geopolitical uncertainty. With traditional ERP systems, it’s difficult to model these risks or test alternative scenarios. Without scenario planning, companies are often caught off guard when issues arise.

These limitations are prompting businesses to seek solutions that go beyond the traditional scope of ERP. Enter digital twins—virtual representations of assets or systems that can integrate with ERP platforms to offer enhanced capabilities.

How Digital Twins Elevate ERP

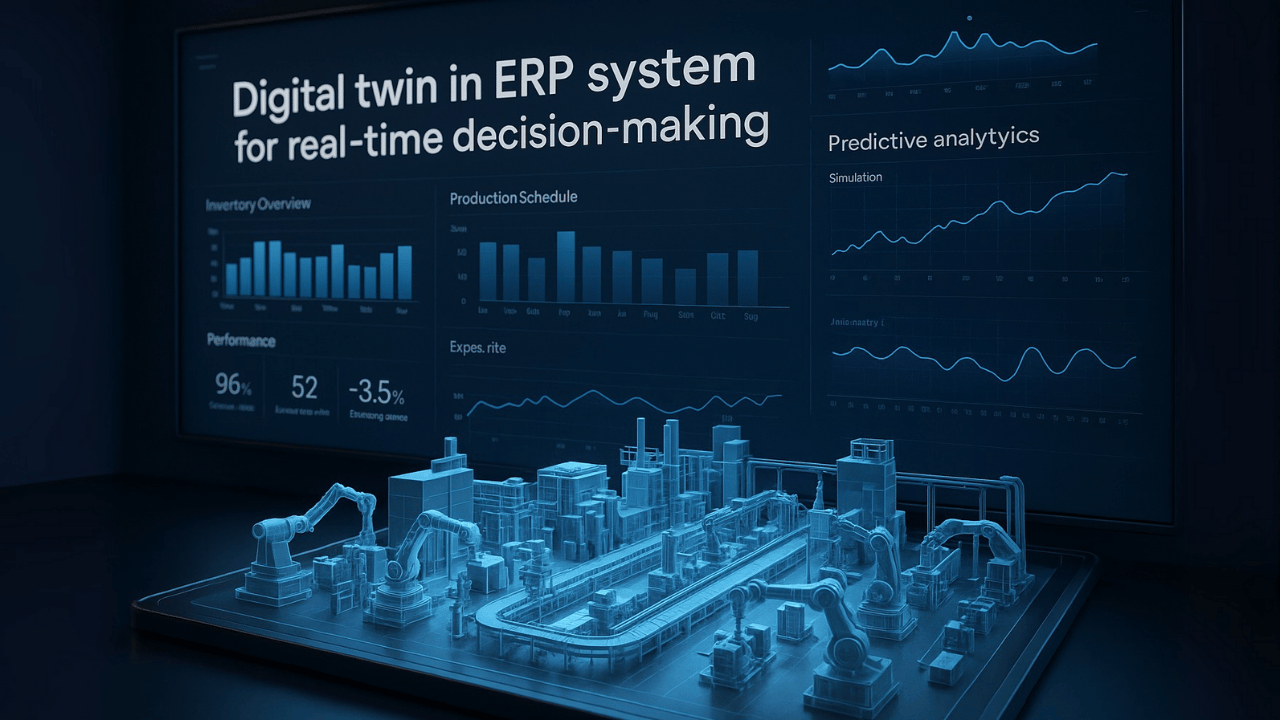

Digital twins bring a whole new level of functionality to ERP systems, allowing businesses to simulate processes, predict challenges, and make more informed decisions. Let’s take a closer look at the key ways in which digital twins elevate ERP:

- Real-Time Process Simulation

One of the most powerful features of digital twins is their ability to model production lines, supply chains, or entire workflows within ERP systems. By virtually simulating these processes, businesses can test scenarios before executing them in the real world. For example, manufacturers can simulate changes in production schedules or test the impact of adding a new product line without interrupting their actual operations.

These simulations not only improve decision-making but also reduce the risk of costly mistakes that could have far-reaching consequences. - Predictive Maintenance & Efficiency

Digital twins can also be used to monitor the performance of physical assets, such as machinery or vehicles, in real time. By mirroring assets digitally, ERP systems can identify potential issues before they occur. For instance, predictive analytics can flag early signs of equipment failure, allowing businesses to schedule maintenance ahead of time and avoid unplanned downtime.

This predictive maintenance capability significantly improves operational efficiency, reduces costs, and extends the lifespan of critical assets. - Smarter Supply Chain Management

In industries like logistics and manufacturing, supply chain disruptions are inevitable. Digital twins, however, enable businesses to run “what-if” scenarios that simulate disruptions, such as delays at ports, shortages of raw materials, or transportation bottlenecks. With this capability, supply chain managers can adjust workflows proactively, optimize inventory levels, and plan for potential risks.

By providing a real-time, dynamic view of the entire supply chain, digital twins help businesses anticipate problems and respond faster to emerging challenges. - Enhanced Decision-Making with AI Integration

When combined with artificial intelligence (AI) and Internet of Things (IoT) data, ERP-powered digital twins can suggest optimal decisions in real time. For example, AI algorithms might recommend adjustments to resource allocation, production schedules, or pricing strategies based on the insights provided by the digital twin.

AI-enhanced decision-making is particularly useful in industries like retail, where businesses must constantly adjust to shifts in demand and consumer behavior. With digital twins, companies can make data-driven decisions that improve efficiency, reduce costs, and enhance customer satisfaction. - Industry Applications

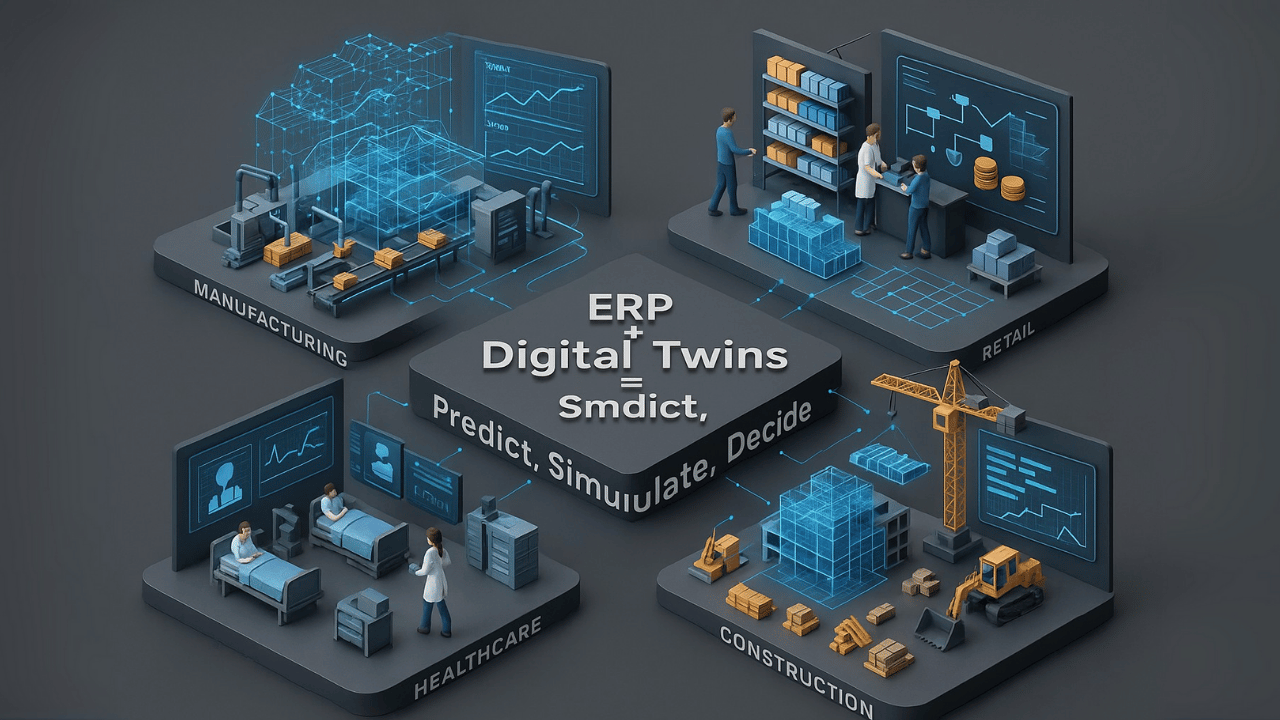

The combination of digital twins and ERP systems is making a significant impact across various industries. Here are just a few examples of how digital twins are transforming specific sectors:- Manufacturing: Manufacturers can use digital twins to simulate plant layouts, identify bottlenecks, and optimize energy consumption. This virtual testing ensures that changes are implemented only after their impact has been thoroughly evaluated.

- Retail: In retail, digital twins can predict demand surges and help businesses test different pricing models. This ensures that retailers can meet customer needs while maximizing profitability.

- Healthcare: Digital twins are increasingly being used in healthcare to manage patient flow and optimize hospital resource allocation. ERP systems integrated with digital twins enable real-time tracking of patient data, helping hospitals improve operational efficiency and patient care.

- Construction: The construction industry benefits from digital twins by simulating project schedules, resource allocation, and material flows. These simulations help identify potential delays, optimize project timelines, and reduce waste.

Data, Stats & Case Study

To further illustrate the impact of digital twins in ERP, let’s look at some key statistics and a real-world example:

- Gartner Prediction (2025): By 2027, over 70% of enterprises will integrate digital twin capabilities into their ERP and supply chain systems.

- Deloitte Research: Companies that use digital twins report a 10–15% reduction in operational costs within two years of implementation.

Case Example: A global automotive company integrated Siemens Teamcenter digital twin technology with SAP ERP. As a result, they achieved a 25% faster production planning process and a 12% reduction in material waste. This integration allowed them to simulate and optimize production processes, improving overall efficiency and reducing costs.

Preparing for the Future of ERP

As businesses increasingly look to future-proof their operations, the integration of digital twins with ERP systems is a key step toward enhanced decision-making, predictive capabilities, and operational agility. Organizations that adopt these technologies will not only react to changes—they will anticipate them, leading to smarter decisions, more resilient operations, and sustainable growth.

At QIC Training & Consultancy, we help businesses navigate the complexities of digital transformation by aligning ERP systems with next-generation technologies such as digital twins, AI, and cloud integration. Our expert team provides the training and guidance necessary to empower your business to leverage these innovations effectively.

👉 Talk to our team to explore how virtual models can make your decision-making smarter and your operations more resilient.

Conclusion

The rise of digital twins in ERP represents a significant leap forward in how businesses manage their operations. By transforming traditional ERP systems from static data trackers into dynamic, predictive ecosystems, digital twins offer the ability to simulate, test, and optimize business processes in real-time. Industries ranging from manufacturing to healthcare are already realizing the benefits of this integration, and as the technology continues to evolve, it will play an even more crucial role in shaping the future of enterprise resource planning. With digital twins, companies are not just reacting to changes—they are proactively shaping their future.

FAQs

From Skills Gaps to Business Wins

From Skills Gaps to Business Wins

Take the First Step.